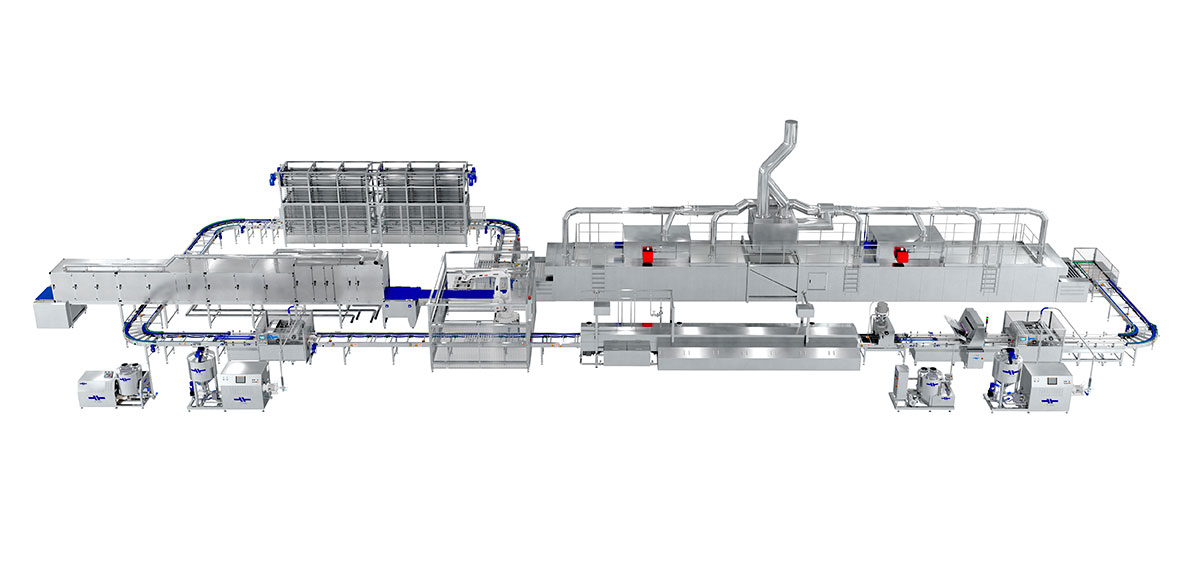

Discover our Cupcake & Deposited Line

Our turnkey industrial Cupcake and Deposited lines are designed and built following our client’s needs and requests for a tailor-made solution.

1

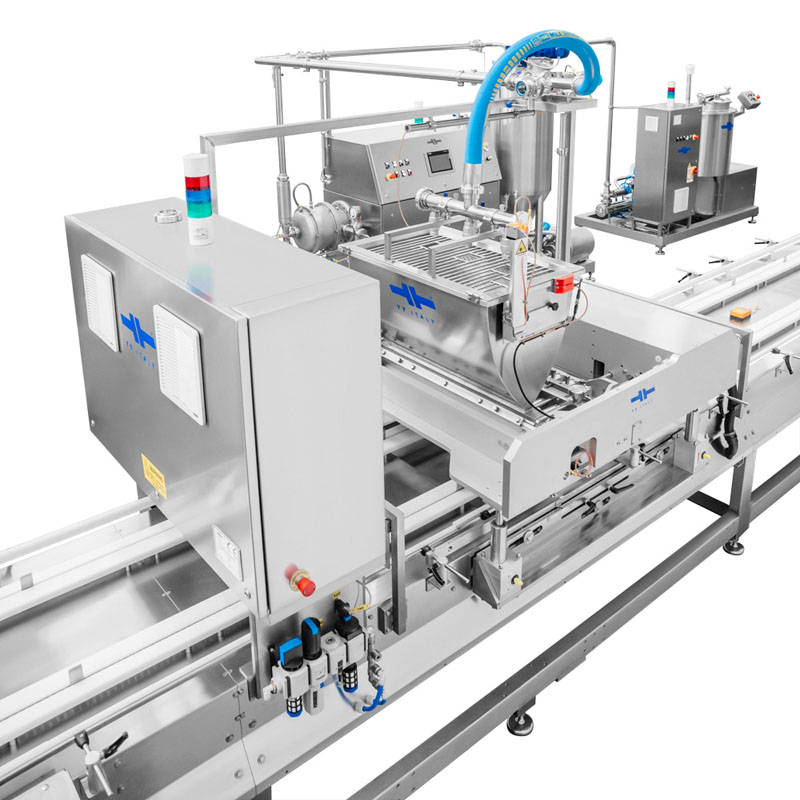

Turbo Mixer Section

Batter & cream preparations

The pre-mixing equipment can be made in various sizes according to the productivity required. We offer two dedicated mixing system, one for batter and one for cream. The turbo mixer (TT Italy Coolwhipper) is designed to emulsify and aerate batter and cream using air, in order to achieve the desired final specific gravity. Emulsification is achieved thanks to the design and building technology of rotor and stator.

C.I.P. UNIT

The C.I.P. (Cleaning In Place) unit is engineered to wash and sanitize production plants (turbo mixers) without the need of disassembling them.

2

PRESSURIZED OIL SPRAYER

Machine designed to accurately grease the product cavities in the baking trays, parametrizable with PLC control. The specific engineering of our machine allows an effective extraction of the cake during the depanning operation, reducing downtime and waste.

3

AUTOMATIC DENESTER

The automatic denester is designed to dispense paper cups of any kind and size. An air-blowing and suction system separates the cups and places them in the desired position, either directly into tray’s cavities or on the conveyor.

4

VOLUMETRIC PISTON DEPOSITOR

TT Italy’s Volumetric Piston Depositor performs a highly accurate dosing of the batter, either in baking trays, paper cups or directly on the conveyor belt. Our tailor-made solutions cater to all productivity volumes and formats. The machine guarantees a constant control of the batter temperature and volume, even in delicate aerated products. Combining the Volumetric Piston Injector with TT Italy’s Turbo Mixer ensures a major control over production parameters, resulting in unmatched final product consistency.

5

TRAYS HANDLING SECTION

A system composed of conveyors, transfers and curves specifically designed to allow the transfer of the trays, from one section of the line to the other, always maintaining the synchronization of speeds and spaces between trays.

6

BAKING SECTION

During the baking section the cake is perfectly baked while controlling the internal moisture of the product. Ovens divided in different baking zones give complete control over the baking process of the final product.

7

COOLING SECTION

COOLING TOWER

TT Italy’s Cooling Tower carries out the continuous cooling process of cakes in trays. Displacing the trays vertically diminishes the line footprint, especially convenient when dealing with space limitations.

COOLING TUNNEL

This innovated equipment is intended for cooling your product. TT Italy’s Cooling Tunnel controls the product’s humidity and the presence of bacteria in the circulating air with active UV treatment. Unlike cooling spirals, the product alignment is maintained, facilitating further operations such as filling injection.

8

VOLUMETRIC PISTON INJECTOR

TT Italy’s Volumetric Piston Injector is designed to accurately inject liquid, viscous or aerated fillings into your products while in trays. Our tailor-made solutions cater to all productivity volumes and format. The machine guarantees a constant control of the filling temperature and volume, even in delicate aerated products. Combining the Volumetric Piston Injector with TT Italy’s Turbo Mixer ensures a major control over production parameters, resulting in unmatched final product consistency.

9

DEPANNING SECTION

TT Italy Depanners are specifically designed to automatically remove products from the baking trays and place them on a dedicated conveyor, maintaining or reconfiguring the product alignment. Special attention is given in engineering the interchangeable depanning heads, tailored to handle delicate aerated products while preserving their integrity.

Robotic depanning is chosen for high productivity and particular applications.

10

ROBOT DECORATOR

This decoration system, combined with TT Italy’s Turbo Mixer, enables the fully automatic decoration process. This system protects the decoration from density and consistency fluctuations and external factors.

The robot decorator is designed to reduce manpower in decoration and engineered to standardize the process, allowing you to create a recognizable product for your brand’s advantage.

11

TRAYS WASHER

This machine efficiently washes and dries the empty trays, ensuring the operation of the line in compliance with the highest hygiene standards. The machine is specifically designed for water saving operations and energy waste reduction.

12

STAND-ALONE MACHINERIES

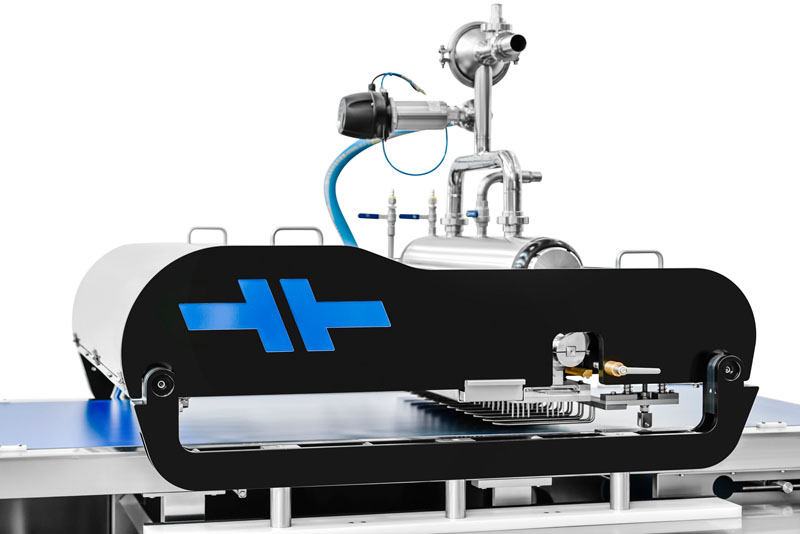

SLIDING VOLUMETRIC PISTON INJECOTOR

TT Italy’s Sliding Volumetric Piston Injector is designed to accurately inject liquid, viscous or aerated fillings into your products while moving on the conveyor belt. The machine is engineered to respond to every client’s requirement, both in product tracking and dosing control, with vertical and horizontal motion. Our tailor-made solutions cater to all productivity volumes and format. The machine guarantees a constant control of the filling temperature and volume, even in delicate aerated products.

TOPPING MACHINE

TT Italy’s Topping Machine is designed to accurately dose toppings onto your product, while it is moving on the conveyor belt. Our tailor-made solutions cater to all productivity volumes and format.

It is engineered for ideal dosing of jams, chocolate and liquid products. Equipped with aligning and phasing systems to guarantee an accurate filling.

COMPACT LINE

This semi-automatic solution features all TT Italy’s most advanced technologies in order to have unparalleled control over the production process.

Compact Line is ideal for start-ups and can be easily converted into a higher productivity industrial solution.